PRODUCT

- Block Making Machine

- Hydraulic Block Making Machine

- Supporting Facilities

- Automactic Cuber System

- Mould

- PVC Pallet

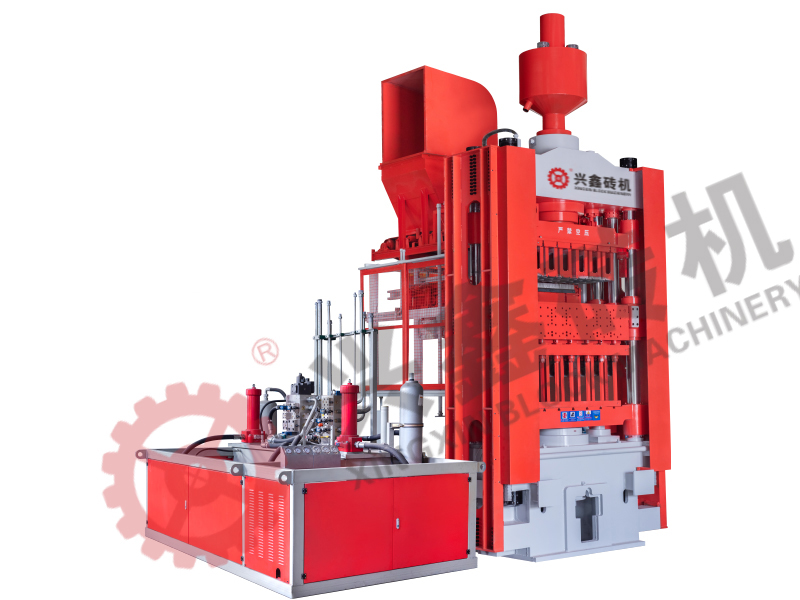

urrent Position:Home > Product > XXT-1300 double way static hydraulic press block machine

Characteristics and uses.

1. High quality integration:

Set machine electro-hydraulic as one, using the brand high and low pressure double oil pump and electro-hydraulic components, improve the forming speed of the static brick press, the equipment is stable, reliable and long life.

2.Automatic precision:

The machine adopts high-precision displacement sensor to detect the position of pressure head, mold frame and material car in real time, uses imported highly sensitive pressure sensor to detect the pressure of the main cylinder in real time, and gives the electric control through the return signal of displacement sensor and pressure sensor. the machine is protected by program interlock, double head two-way pressing molding does not need vibration, the finished product has high accuracy and good compactness.

3. Intelligent control :

The intelligent control system is adopted to realize the interactive control of man-machine dialogue, automatically display the working status of the system, alarm the fault system and display the fault location, which can realize remote diagnosis and repair, and solve the customers' worries.

4. Green environmental protection:

Static pressure molding, green environmental protection, efficient and labor-saving, no vibration noise pollution, after forming, it can be palletized and stacked without supporting plates, reducing the occupation of the site.

5. A wide range of applications:

Turning waste into treasure, solid waste materials have a wide range of adaptation, and more bricks can be produced.

This machine is widely used in the production of soil, mining and construction waste products, and is more suitable for the production of standard bricks, eight-hole bricks, large hollow bricks and other building blocks.

Within the range of molding, the mold can be replaced to produce block products of various specifications, and only the plate needs to be replaced after the wear of the same type of mold.

6. High performance-price ratio:

Environmental protection static press brick machine comprehensive economic benefits, environmental benefits, social benefits are the best.

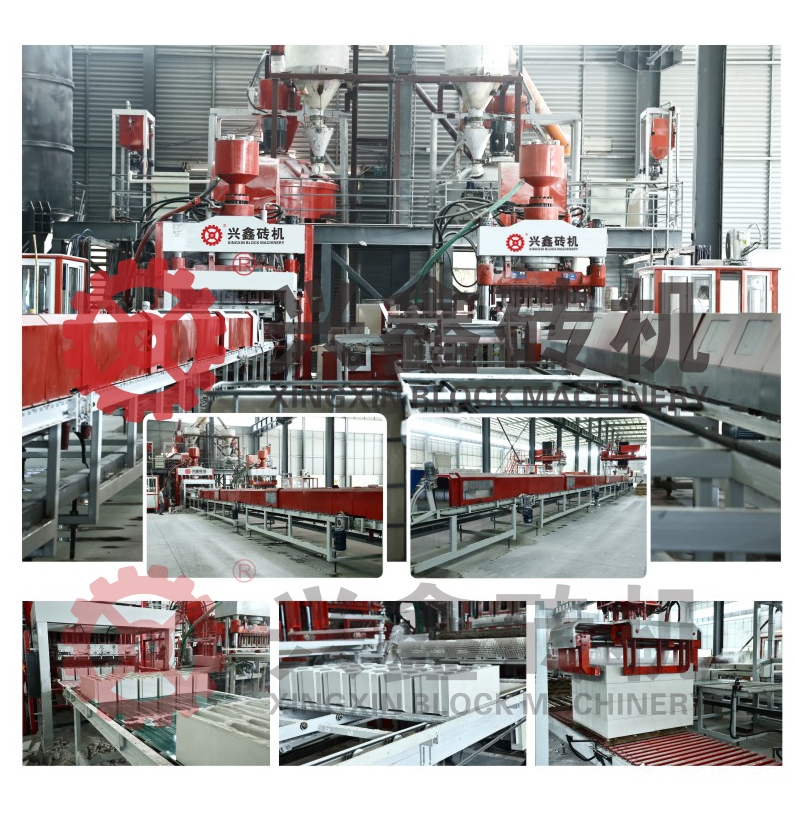

On-site case of positive double pressure static press for phosphogypsum:

Equipment characteristics:

Unique mixing mode, secondary atomization intelligent induction water addition, accurate distribution system, coordination of compression ratio and pressure, intelligent electronic control one-button start, high-voltage mute, no need for drying, artificial intelligence palletizing brick collection.

Analysis and comparison of semi-dry formed gypsum block and traditional formed phosphate block.

Traditional phosphogypsum blocks are usually produced by casting:

This mode of production has the advantages of high water-cement ratio, long drying cycle and high cost.

It is not conducive to the large-scale and continuous production of gypsum products, can not meet the needs of project construction, but also can not adapt to the mass utilization of industrial by-product gypsum.

Although the density of gypsum hardened body produced by casting method is light, it has long drying period, low hardness, low strength, high handling damage rate and low market recognition.

These factors not only seriously restrict the development of the application of phosphogypsum building materials, but also make the comprehensive utilization rate of phosphogypsum resources on the low side, which is not conducive to improve the digestibility of phosphogypsum and the comprehensive efficiency of related industries. Therefore, it has always been the pursuit and desire of manufacturers to reduce the ratio of water to paste, reduce the drying cost, shorten the production cycle, improve product strength and quality, and expand market acceptance.

Semi-dry gypsum block production, the main material is building gypsum, adding a small amount of special auxiliaries, building gypsum special auxiliaries, building gypsum hydration reaction and crystal nucleus formation for crystal adjustment and setting, with a unique molding mode, so that hydrogen bonds and crystal nuclei in the hydration reaction work together to improve the strength of the block, each index far exceeds the gypsum block JC/T698-2010 standard requirements.

The key to semi-dry gypsum gel technology is to reduce the ratio of water bags produced by gypsum blocks to about 30%.

In this way, the hydration reaction is more intense than the traditional pouring method, and the temperature is about 10 degrees higher than the pouring method, which effectively shortens the drying period.

In this process, by adding auxiliaries, crystal adjustment and dispersion homogenization are carried out to ensure that the hydration reaction is normal and fully carried out.

This semi-dry production technology of reducing water-cement ratio makes the gypsum products can be packed into storage or wide range without drying or drying, which greatly shortens the production cycle and production cost of stone block.

At the same time, with the successful development of auxiliaries, gypsum cementitious materials have the main functions of crystal adjustment, setting, separation and prevention, and can appropriately adjust the proportion of different gypsum to meet the requirements of production and performance.

The performance of semi-dry gypsum cementitious products is excellent and the cost is low, which expands the development space of gypsum products.

It also has a wide range of applications, such as all kinds of standard bricks, hollow bricklaying, combined strips, fireproof boards, paper plasterboards and so on. Because the semi-method makes use of the hydration and hardening mechanism of gypsum, and breaks through the concept of water requirement for consistency of pouring method.

Therefore, it is possible to be used in the production and application of antistatic floor gypsum core materials and all kinds of stone bone hardening materials in the future.