PRODUCT

- Block Making Machine

- Hydraulic Block Making Machine

- Supporting Facilities

- Automactic Cuber System

- Mould

- PVC Pallet

urrent Position:Home > Product > XXT-800 double way static hydraulic press block machine

Characteristics and uses.

1. High quality integration:

Set machine electro-hydraulic as one, using the brand high and low pressure double oil pump and electro-hydraulic components, improve the forming speed of the static brick press, the equipment is stable, reliable and long life.

2.Automatic precision:

The machine adopts high-precision displacement sensor to detect the position of pressure head, mold frame and material car in real time, uses imported highly sensitive pressure sensor to detect the pressure of the main cylinder in real time, and gives the electric control through the return signal of displacement sensor and pressure sensor. the machine is protected by program interlock, double head two-way pressing molding does not need vibration, the finished product has high accuracy and good compactness.

3. Intelligent control :

The intelligent control system is adopted to realize the interactive control of man-machine dialogue, automatically display the working status of the system, alarm the fault system and display the fault location, which can realize remote diagnosis and repair, and solve the customers' worries.

4. Green environmental protection:

Static pressure molding, green environmental protection, efficient and labor-saving, no vibration noise pollution, after forming, it can be palletized and stacked without supporting plates, reducing the occupation of the site.

5. A wide range of applications:

Turning waste into treasure, solid waste materials have a wide range of adaptation, and more bricks can be produced.

This machine is widely used in the production of soil, mining and construction waste products, and is more suitable for the production of standard bricks, eight-hole bricks, large hollow bricks and other building blocks.

Within the range of molding, the mold can be replaced to produce block products of various specifications, and only the plate needs to be replaced after the wear of the same type of mold.

6. High performance-price ratio:

Environmental protection static press brick machine comprehensive economic benefits, environmental benefits, social benefits are the best.

Some finished products samples and output capacity:

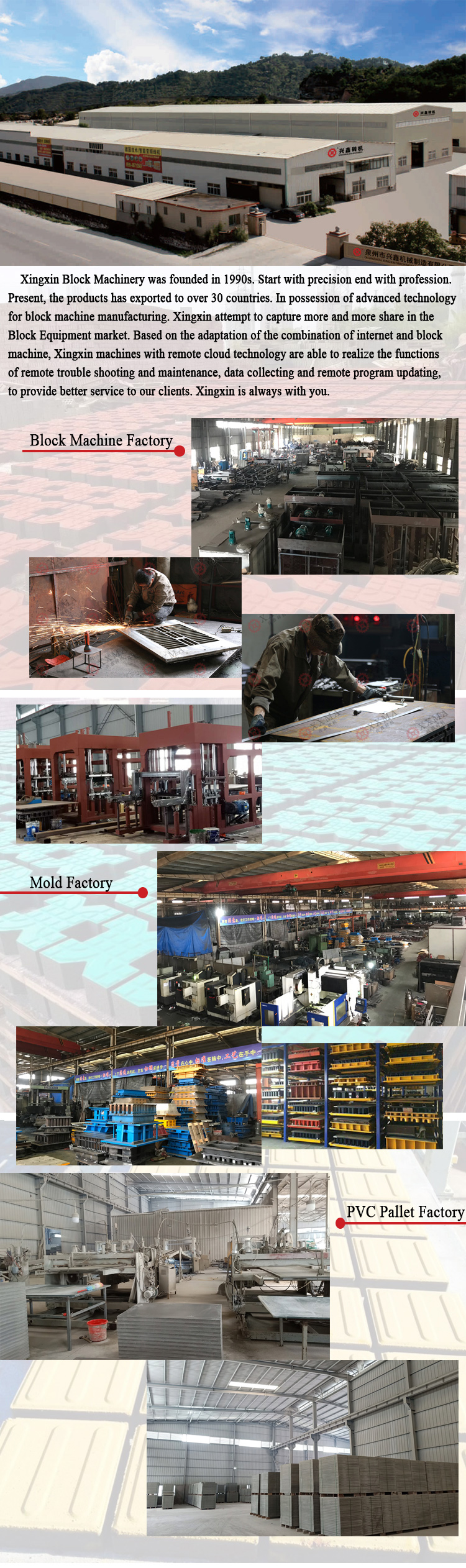

About us:

FAQ

Q1: what are your advantages?

Almost 30 year experience so we can provide more professional suggestion, installation and commission, training service etc for you. With 10 years trading experience, our products have been exporting to over 45 countries. And our prices are more reasonable with the same high quality.

Q2: What kind of products you can supply ?

Our main products are concrete brick making production line include host machine, concrete mixer, batching machine, block stacker,PVC pallet or bamboo pallet, block mold, pigment feeder, automatic pallet feeder device, cement silo, cement scale, screw conveyor, trolley etc.

Our common block machine (molding method is hydraulic with vibration) models are from QT3-15 to QT18-15.

And 100% STATIC hydraulic press block machine models are XXT-500; XXT-600, XXT-900 AND XXT-1300.

Q3:Terms of Payment?

30% by T/T as deposit, 70% balance payment by T/T before shipment or 100% by confirmed, irrevocable L/C at sight.

Q4: How about delivery time?

30-35 days after receipt of deposit and molds are fully confirmed from Buyer.

Q5:How about guarantee period ?

One year after installation finished at buyer's factory.

QT6: How about installation service:

Our company could send one or two of our engineers to buyers' place to direct the installation and give the operation training.

Q7:How about transport packaging?

Nude packing or packed with plastic wrap or as buyer’s requirements!

Almost 30 year experience so we can provide more professional suggestion, installation and commission, training service etc for you. With 10 years trading experience, our products have been exporting to over 45 countries. And our prices are more reasonable with the same high quality.

Q2: What kind of products you can supply ?

Our main products are concrete brick making production line include host machine, concrete mixer, batching machine, block stacker,PVC pallet or bamboo pallet, block mold, pigment feeder, automatic pallet feeder device, cement silo, cement scale, screw conveyor, trolley etc.

Our common block machine (molding method is hydraulic with vibration) models are from QT3-15 to QT18-15.

And 100% STATIC hydraulic press block machine models are XXT-500; XXT-600, XXT-900 AND XXT-1300.

Q3:Terms of Payment?

30% by T/T as deposit, 70% balance payment by T/T before shipment or 100% by confirmed, irrevocable L/C at sight.

Q4: How about delivery time?

30-35 days after receipt of deposit and molds are fully confirmed from Buyer.

Q5:How about guarantee period ?

One year after installation finished at buyer's factory.

QT6: How about installation service:

Our company could send one or two of our engineers to buyers' place to direct the installation and give the operation training.

Q7:How about transport packaging?

Nude packing or packed with plastic wrap or as buyer’s requirements!